Product overview

APMT (Advanced Power Modular Transporter) full road condition module trailer is a new type of road/site transportation multi-function vehicle designed and developed by our company. It's an unique system design can meet the self-drive under low-speed site handling, and at the same time. It can meet the normal load in the 80km/h speed traction mode, and can adapt to the needs of large-scale transportation in multiple scenarios and all road conditions.

ONE,APMT Product introduction

1. Hydraulic drive module car

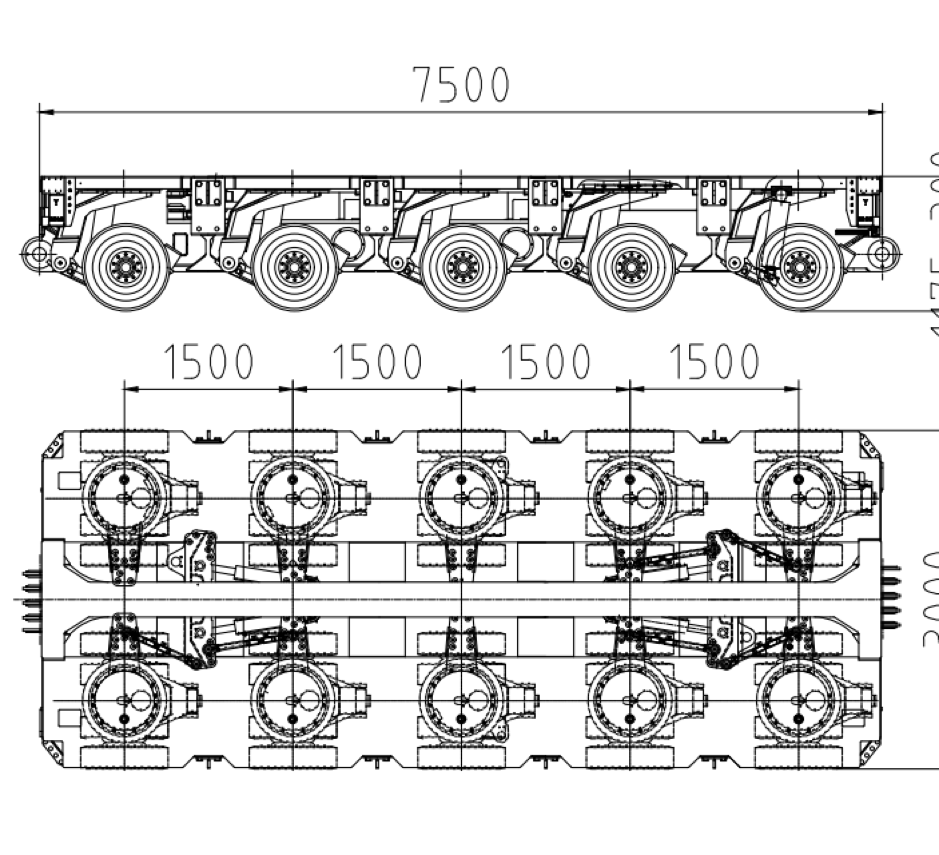

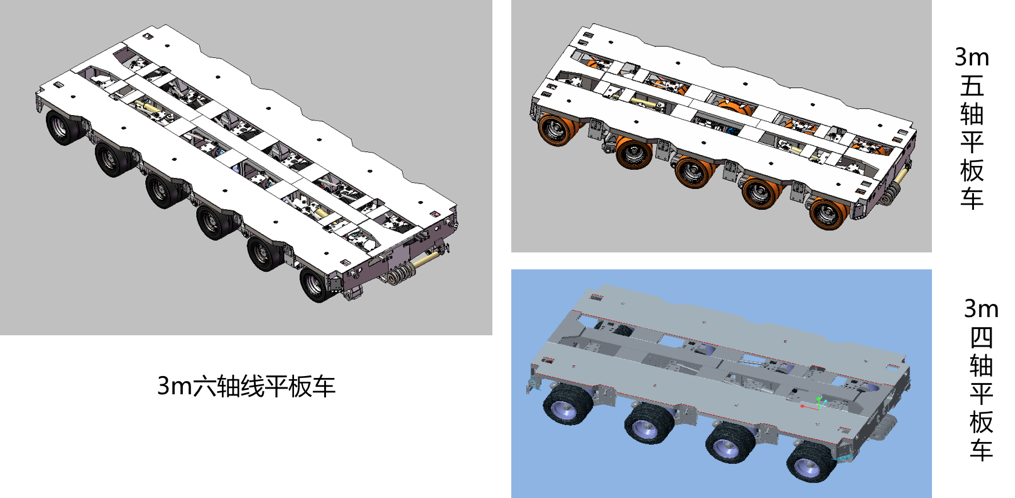

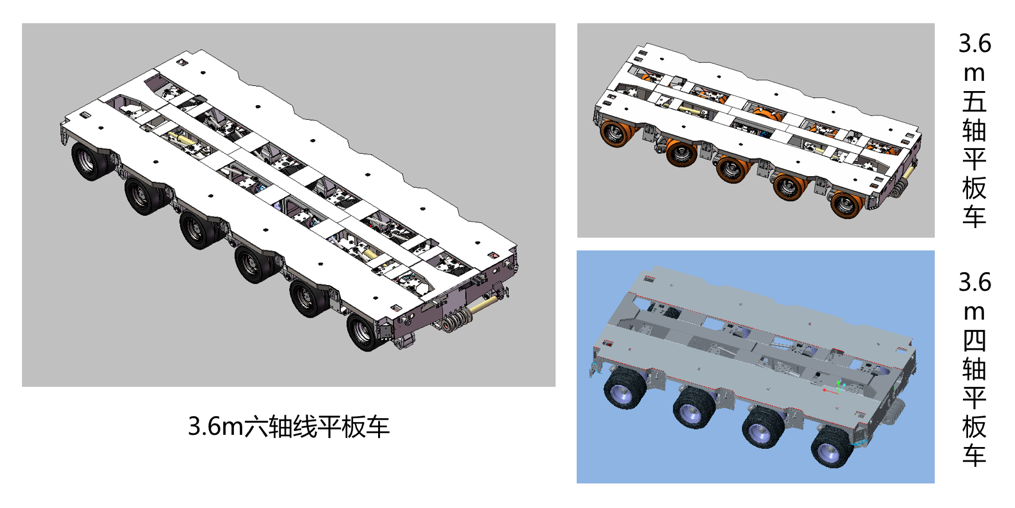

Hydraulic drive APMT has 4 axes, 5 axes and 6 axes, and the plate width is 2.43m, 3m and 3.6m, which can meet different operation needs.

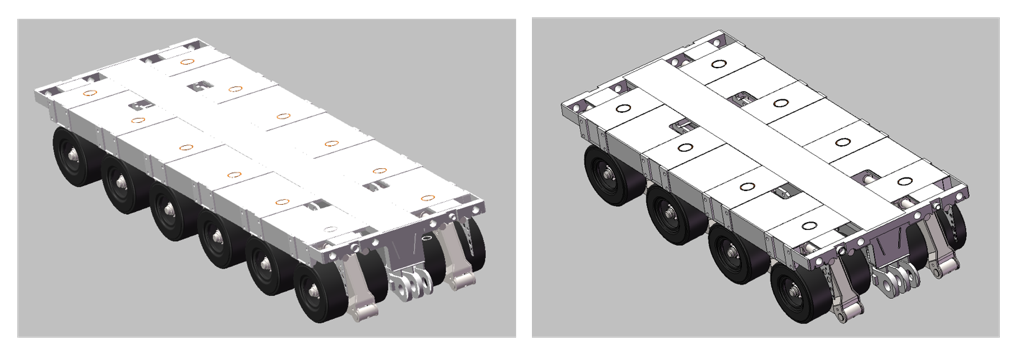

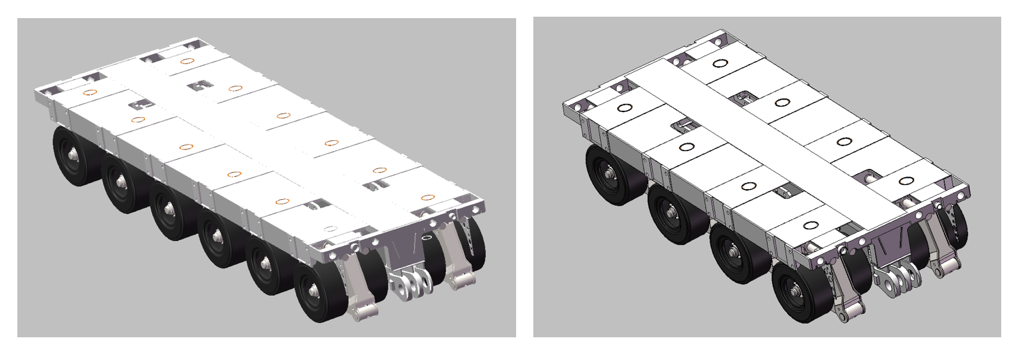

The hydraulic drive axle shown in the picture is now equipped with a 2.43m APMT flatbed modular car. The picture on the left is a six-axis modular car, and the picture on the right is a four-axis modular car.

The hydraulic drive axle shown in the picture is now equipped with a 2.43m APMT flatbed modular car. The picture on the left is a six-axis modular car, and the picture on the right is a four-axis modular car.

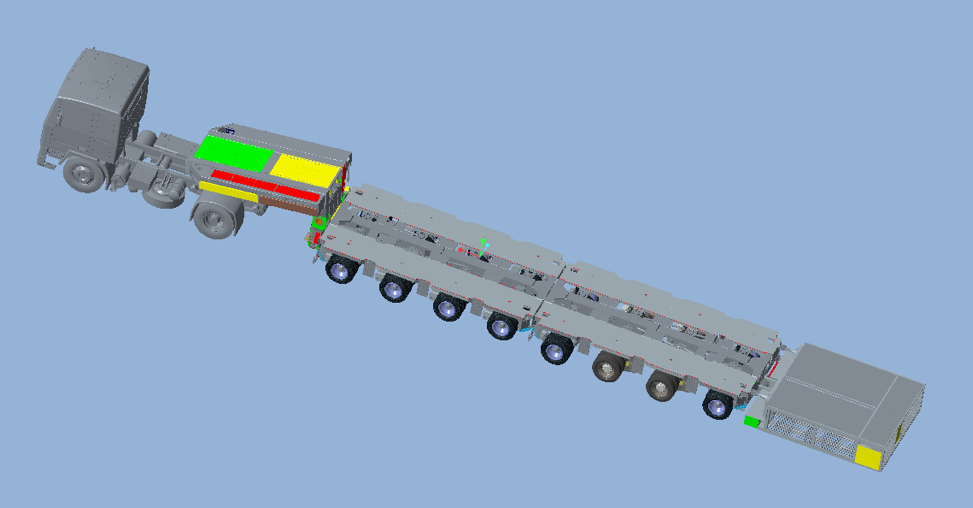

The picture shows the assembly method of the traction mode of the 4-axis APMT unit. It consists of a towing vehicle + gooseneck + ordinary hydraulic trailer + APMT + PPU. This state can be pulled and walked on the highway with a load (the drive axle also carries), and the maximum speed is 80Km/h. The axles are equipped with braking systems.

APMT3600 is the first APMT model, suitable for 400T-class transportation of complete vehicle loads. The main features are as follows

> Self-developed drive axle system, which can implement free switching between self-driving mode and traction mode;

> With its own power system unit, it can be transported at low speed;

> The whole vehicle can meet the high-speed traction transportation with a maximum speed of 80km/h

> Active hydraulic suspension, vehicle lift, automatic load balancing, adaptive landing gear attitude.

2、,Electric drive module car

The picture shows that the electric drive axle is now matched with a 2.43m APMT flat panel module car, the picture on the left is a six-axis line module car, and the picture on the right is a four-axis line module car; at the same time, the electric drive axle can also be matched with a 3m, 3.6m four-axis line, five-axis line, six-axis line APMT flat panel module car.

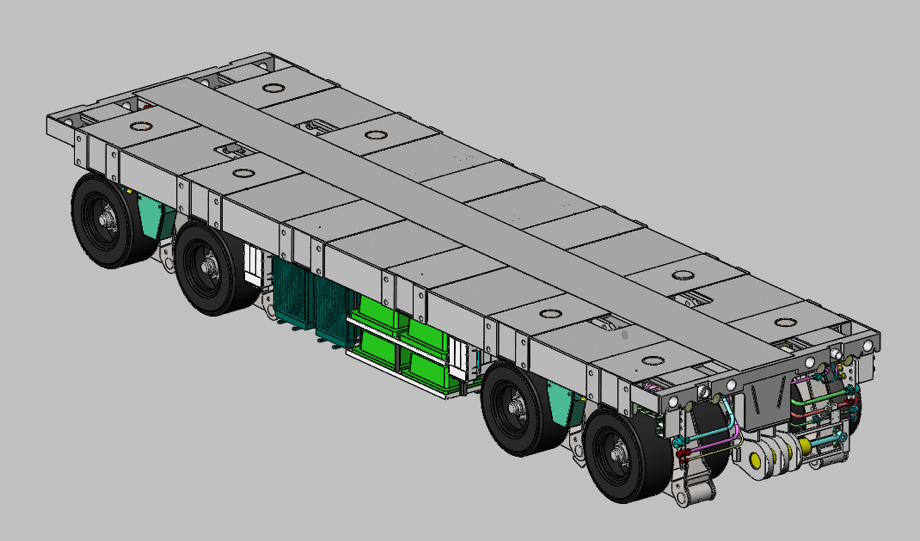

The picture shows the APMT new energy power module using an electric drive axle. The module is equipped with a power battery and an electronic control system

THREE,APMT Core Technology

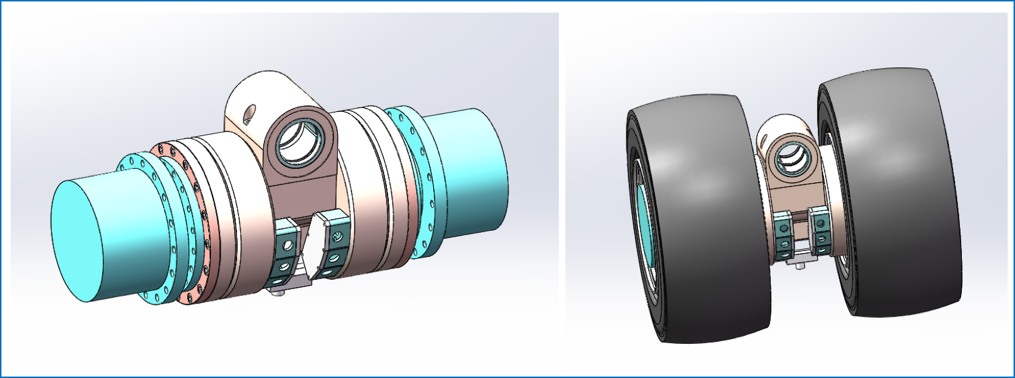

1.Hydraulic drive axle

The picture shows the APMT hydraulic drive axle, which provides driving force for the vehicle through the operation of the hub hydraulic motor. The hydraulic drive axle composed of the hub hydraulic motor is used with general-purpose tires through special rims.

2,Electirc drive axle

The picture shows the APMT electric drive axle, which is assembled with a gear reducer and rim through a self-developed hub motor to provide power for the vehicle to walk.

3,APMT Application cases

1. se the large-scale hoisting equipment matched by our company's hydraulic drive axle for slope climbing test in the factory area.

2. Use the large-scale hoisting equipment matched by our company's hydraulic drive axle to walk on the site.

4.APMT Advantage

1. The process of large-scale transportation of traditional vehicles often requires multiple towing vehicles to work together;

2. The mountain road, uphill and downhill sections need to be towed by engineering vehicles such as loaders

3. The drive axle of the traditional self-driving hydraulic module vehicle in the traction mode (high-speed driving) cannot bear the load, and only the driven axle bears the load.

At a vehicle speed of 10km/h, 2 sets of drive axles per axis can provide a traction force of 78kN, which is equivalent to the traction force of two 400-horsepower towing vehicles by converting a 4-axis APMT (where the 3-axis is the drive axle).

Under the premise of not adding additional vehicles, the APMT solution uses self-developed drive axles to replace the existing driven axles, thereby reducing the use of towing vehicles and construction machinery in large-scale transportation operations, so as to improve operation efficiency, reduce operation risks, and reduce operation costs. purpose.

It is especially suitable for mountain climbing, self-driving, and does not need to borrow other power to drag. It can also be used for small transportation sites, small turning radii, and low-speed short-distance transportation of large-tonnage goods, such as shipping terminals, freight yard turnover and bridge construction sites, etc. It saves the reversing link of goods in high-speed sections and low-speed sections, saving transportation costs and transportation time.

The APMT scheme can be customized according to different needs, and different numbers of drive axles can be used to optimize the overall cost while ensuring the operating capacity.