Product overview

Introduction:

2017.01——China's first pure electric remote-controlled tow-barless aircraft towing vehicle eTV90 prototype rolls off the production line and begins verification testing.

2018.11——The eTV90 prototype obtained the first test report after passing all test items in the test outline.

2019.12——China's first pure electric remote control tow-barless aircraft towing vehicle eTV90 production car officially released.

eTV90 is the world's first cockpit remote-controlled electric tow-barless aircraft towing vehicle with optional cockpit. It is also the first electric tow-barless aircraft tractor in China.

ONE,Productintroduction

1. The landing gear safety pins are interlocked to ensure that the clamping operation is carried out in the free rotation state of the landing gear.

2. One-key clamp, automatic connection, manual automatic free switch. Logic control clamp landing gear operation.

3. Equipped with wireless remote control emergency stop button, the crew can stop the vehicle in emergency.

4. Active hydraulic suspension, vehicle lifting, automatic load balancing, adaptive landing gear attitude.

5. The dual-motor power system is redundant to prevent on-site shutdown.

6. Pure electric, zero emission, maximum continuous operation of 50 sorties.

7. Automatically identify the aircraft type,independently select the holding clip and traction parameters.

TWO,Product parameters

THREE,Product advantages

>> Security aspects

1.Error-proof design:Through the analysis and research of the workflow of each step of aircraft traction and wheel holding, it is found that the installation and removal of the aircraft front wheel turning pressure relief pin, an indispensable manual intervention link, is relatively prone to errors. We considered solving this problem from this source when designing the product, and transformed passive remediation into active prevention.

The first is to design the towing vehicle's model selection safety pin to be the same as the aircraft's front wheel turning pressure relief pin, which can completely replace the aircraft's front wheel turning pressure relief pin during the working process. Select the installation position of the safety pin through the towing vehicle's model to inhibit or activate the towing vehicle's related work functions or states

Transform passive remediation into active prevention and reduce the safety pressure of front-line workers and units on site.

The second is to strictly control each work link or node in combination with the workflow of each step of aircraft traction and wheel holding, so as to ensure that the entire aircraft traction work is completed according to the workflow, effectively avoid human factors from the source, reduce the occurrence of errors, and reduce the onsite. The safety pressure of personnel and units.

One-key clamp, automatic connection, manual automatic free switching

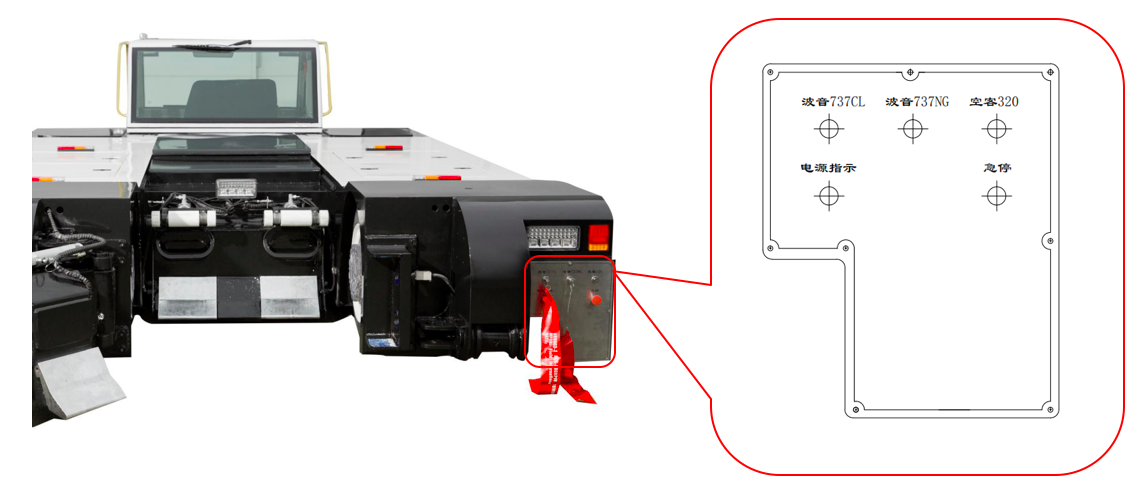

2. Emergency stop button

During the process of aircraft traction, abnormal situations are more likely to occur, especially when the space for entering and leaving the hangar and abutting the bridge is relatively narrow. In the event of an emergency, the staff can actively and directly operate the emergency stop button anytime and anywhere to control the emergency stop of the towing vehicle, reducing the link of intermediate information communication, saving time, and avoiding aircraft scratches in a timely and effective manner.

Emergency stop button: active control to effectively avoid aircraft scratching.

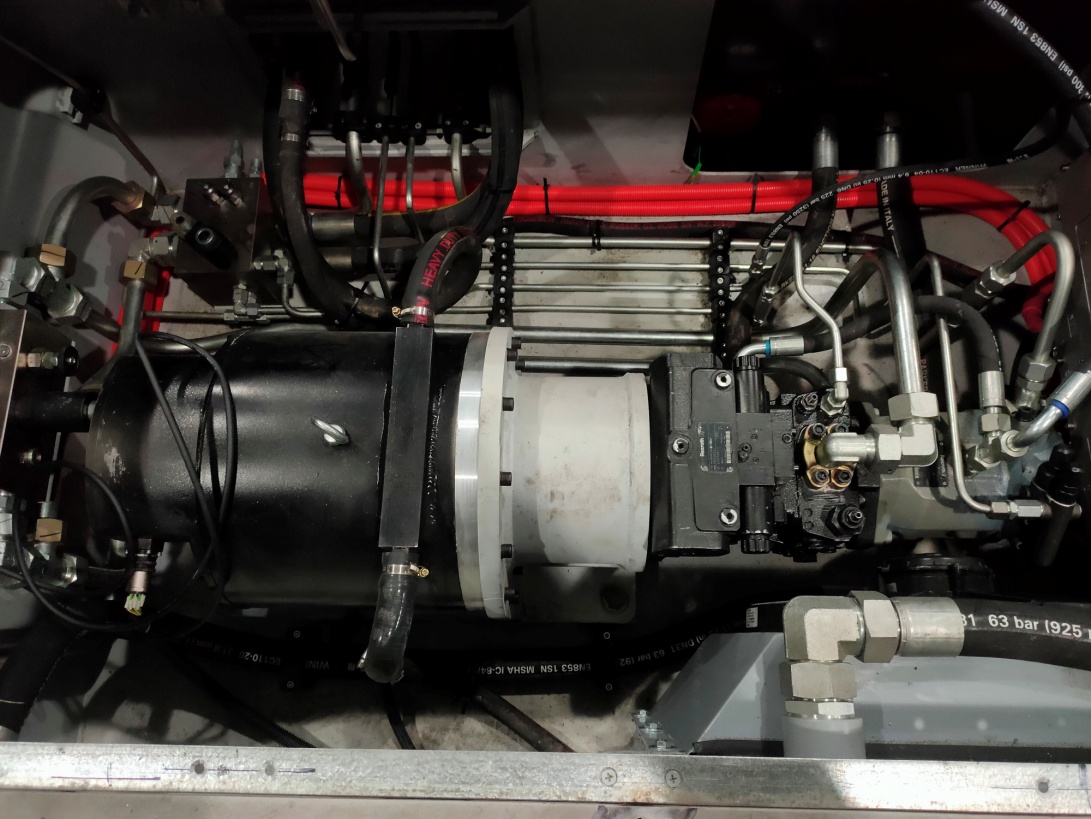

>>The dual motors are redundant, using smokeless lithium iron phosphate battery, high reliability

The double motors each drive a set of hydraulic pump groups to work, which can work with a single motor or double motors at the same time, with high reliability.

The battery adopts a fireproof lithium iron phosphate battery pack, equipped with an advanced BMS system to monitor the temperature of each cell in real time to prevent overcharging; equipped with an in-box fire extinguishing system.

>> Efficiency,Energy-saving,Dexterity

1. The operator is the observer, and one person can complete the movement of the aircraft.

2. Pure electric drive, only 1 kWh of electricity is needed to push the B737/A320 aircraft 500 meters.

3. Flexible operation, the towing vehicle can travel under the belly, saving the aircraft hangar space.

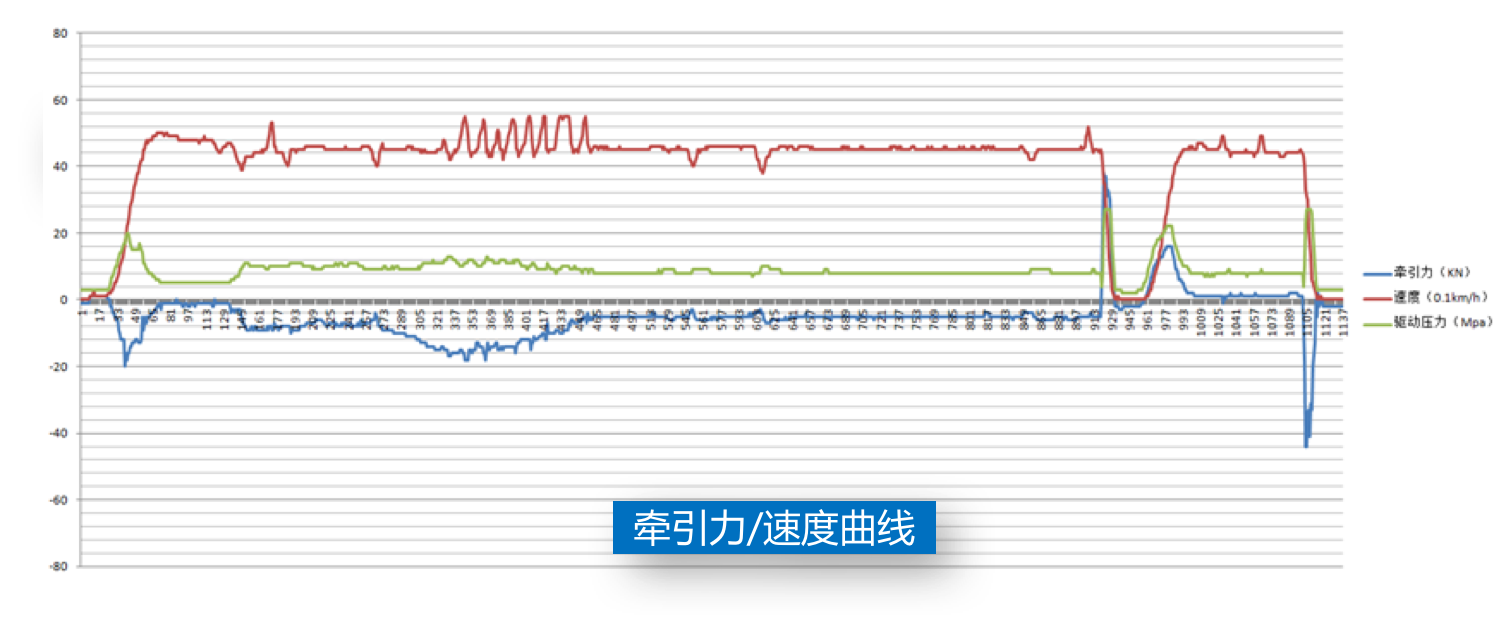

>> Test system for testing outline requirements

FOUR,Product comparison

Advantages of eTV90

1. A multi-purpose pure electric mop-free tractor that can completely replace fuel towing vehicles.

2. Fast speed, large gap from the ground, can be operated in the whole airport.

3. Optional hatch cover can work around the clock.

4. High-voltage lithium battery pack, fast charging speed and no pollution.

FIVE,Testing projects of eTV90

Civil aviation testing standards total the 18th CPC National Congress and 135 sub-tests. On the basis of compatibility with Boeing, Airbus-related and aircraft supporting test projects, the whole vehicle testing has been improved

SIX,The application of eTV90

eTV90 will go to Tianjin Civil Aviation University for real machine trial in June 2021.

SEVEN,eTV90-SD pure electric tow-barless aircraft towing vehicle standard.

eTV90 multi-function pure electric remote control tow-barless aircraft towing vehicle is produced by Titan Technology, which conforms to MH ** "Tow-barless aircraft towing vehicle (electric type) testing outline" and is suitable for jacking and long-distance towing operations.

The maximum traction mass of eTV90 is 98 tons, covering C919, B737 and A320 and other models. The main features are as follows:

1. 1.Pure electric, zero emission, maximum continuous operation of 50 sorties.

2. Active hydraulic suspension, vehicle lifting, automatic load balancing, adaptive landing gear attitude.

3. Logic control telescopic single claw, the whole frame is stressed, and the vehicle has light weight.

4. Automatically identify the aircraft type, independently select the holding clip and traction parameters, and man-machine safety interlock ensures safe operation.

5. Double power system backup each other, high reliability

eTV90 pure electric no-mop aircraft towing vehicle cockpit model.

eTV90 pure electric no-mop aircraft towing vehicle cockpit model.

eTV90 multi-function pure electric remote control tow-barless aircraft towing vehicle is produced by Titan Technology, which conforms to MH ** "Tow-barless aircraft towing vehicle (electric type) testing outline" and is suitable for jacking and long-distance towing operations.

eTV The maximum traction mass of eTV90 is 98 tons, covering C919, B737 and A320 and other models. The main features are as follows:

1. Pure electric, zero emission, maximum continuous operation of 50 sorties

2. Active hydraulic suspension, vehicle lifting, automatic load balancing, adaptive landing gear attitude.

3. Logic control telescopic single claw, the whole frame is stressed, and the vehicle has light weight

4. Automatically identify the aircraft type, independently select the holding clip and traction parameters, and man-machine safety interlock ensures safe operation

5. Double power system backup each other, high reliability.

6. The cockpit model is equipped with a separate hatch cover, equipped with a seat control handle, and a landing gear attitude visual monitoring system.